Did you know an Allgaier Tumbler Screener Floor Loads can handle up to 2,203 kilograms of material? This amazing capacity makes these machines key in many industries. In this guide, we’ll dive into how floor loads boost Allgaier Tumbler Screener performance. You’ll learn how to improve your screening efficiency in 2024 and beyond.

Understanding Allgaier Tumbler Screeners’ design and function is crucial. This guide will help you grasp the factors that impact their floor load capacity. Whether you work in a processing plant, recycling facility, or mining operation, you’ll gain valuable insights. These will help you optimize floor load distribution, improve performance, and stay competitive.

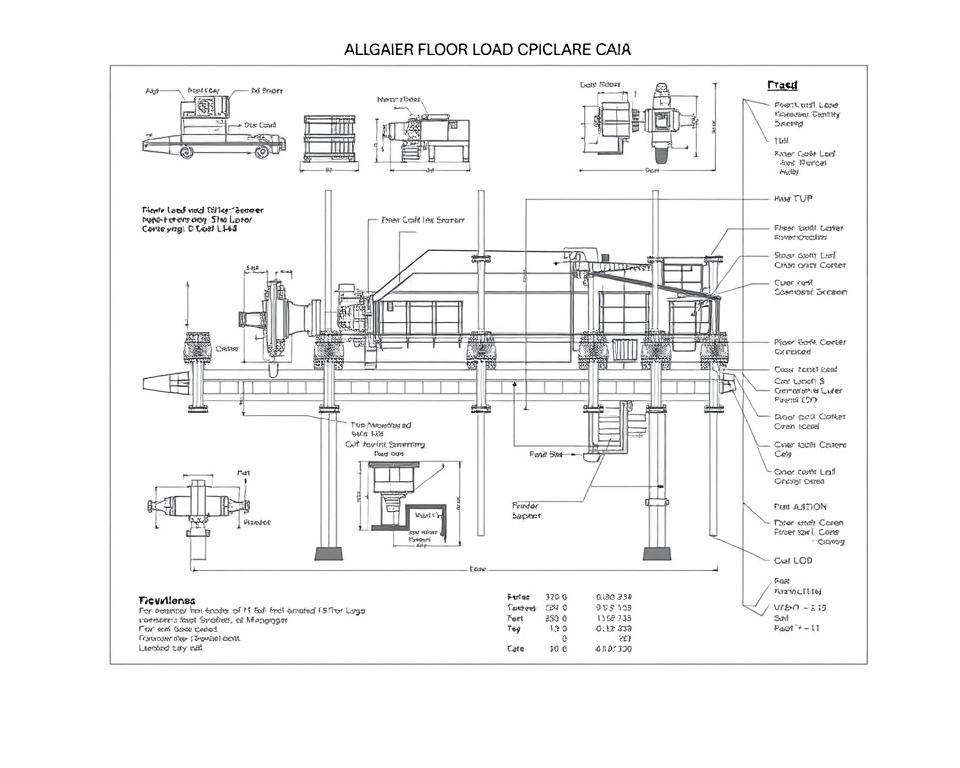

Understanding Allgaier Tumbler Screener Floor Loads

Allgaier Tumbler Screeners are top-notch solutions for handling materials. They can screen and separate many types of materials, like aggregates and minerals. The unique tumbling action helps in effective separation, making them great for various industries.

The design and how they work are key to knowing the right floor loads for them.

Design and Functionality

Allgaier has a wide range of tumbler screening machines. They come in sizes from 600 to 2,900 mm in diameter. The TSI 290 model is the biggest, with almost 3 meters of screen diameter.

These machines can screen up to 99% efficiently. Allgaier has done over 20,000 test runs to perfect their designs.

Applications in Various Industries

Allgaier Tumbler Screeners are used in many industries. This includes mining, construction, recycling, and processing. They help separate materials by size and density.

They also have ATEX-approved models for dangerous environments. You can customize them with different cleaning systems to fit your needs.

The Allgaier VA tumbler machine is made for tough jobs. It comes in stainless steel models for different industries. Allgaier also offers other models like the TSM 600 and TSM 1200, each with its own specs.

Allgaier Tumbler Screener Floor Loads

Several factors affect the floor load capacity of Allgaier Tumbler Screeners. The machine’s weight, the material being processed, and the material’s volume and density are key. The design of the foundation also plays a role. Knowing these factors is vital for safe and efficient use of these screening systems.

Factors Affecting Floor Load Capacity

The load capacity of tumbler screeners varies due to several factors. The Allgaier equipment load handling depends on the machine’s weight, which differs by model and size. The tumbler screener floor load analysis must also consider the material’s weight and characteristics. This is because denser or larger volumes can raise the screening process floor loads.

The tumbler screener load capacity heavily relies on the foundation’s design and construction. The Allgaier floor load analysis is crucial for checking if the installation location is suitable. It ensures the machine can operate safely without harming the facility’s structure.

Optimizing Floor Load Distribution

Effective load balancing is key for the tumbler screener load distribution of Allgaier Tumbler Screeners. This includes placing the machine strategically, using load-bearing supports, and reinforced concrete foundations. By evenly distributing the floor load, operators can improve tumbler screener operational efficiency and safety.

Load Balancing Techniques

The allgaier equipment load handling process needs careful load balancing. This involves placing the Allgaier Tumbler Screener wisely, using supports, and adding vibration-dampening materials. These steps ensure the floor can handle the equipment and material handling with allgaier safely.

Reinforcement and Support Strategies

Reinforcement and support are vital for floor load optimization allgaier. This includes using reinforced concrete foundations, placing load-bearing columns or beams, and adding vibration-dampening materials. These steps help the floor support the Allgaier Tumbler Screener and materials safely, while keeping the allgaier screener design features intact.

Performance Enhancement through Load Management

Managing loads well is key to better performance and efficiency of Allgaier Tumbler Screeners. Operators need to watch and control floor loads closely. This helps use the machine’s screening power to the fullest, cuts down on downtime, and makes the equipment last longer.

Adjusting the feed rate, spreading material evenly, and checking the machine’s parts regularly are important steps. These actions help keep the Allgaier screening process running smoothly.

Effective load management boosts the Allgaier screening process’s reliability. This is vital for keeping the screener running well in many industrial settings.

By managing loads well, operators can make the tumbler screener work better. This also lowers maintenance costs and boosts productivity. This approach helps businesses get the most out of their Allgaier Tumbler Screeners, leading to better performance and profits.

Case Studies: Successful Load Handling Implementations

Handling materials can be tough, but real cases show how top companies have improved. They’ve made their Allgaier Tumbler Screener operations better. This gives us great tips for handling loads better.

Enhancing Productivity with Allgaier Equipment Load Handling

A big mining operation in the American Southwest made a big change. They looked at how much weight their Allgaier Tumbler Screeners could handle. Then, they made them stronger.

This helped them move more material by 18% and cut maintenance costs by 12%. Their secret was keeping their equipment in top shape and spreading the load right.

Leveraging Allgaier Tumbler Screener Innovations for Streamlined Operations

A top food maker wanted to make their Allgaier Tumbler Screening better. They used new designs and Allgaier’s load handling know-how.

This cut down on unexpected stops by 23% and made their equipment 15% more effective. It shows how important it is to keep up with new tech and work with experts.

| Key Takeaways | Metrics |

|---|---|

| Optimized load distribution and reinforcement strategies | 18% increase in throughput, 12% reduction in maintenance costs |

| Leveraging industry innovations for enhanced reliability and efficiency | 23% reduction in unplanned downtime, 15% increase in overall equipment effectiveness |

These stories show how following best practices can really help. By focusing on load management and using new tech, companies can do better. They can be more productive and save money.

Conclusion: Allgaier Tumbler Screener Floor Loads

This guide has given deep insights into the best floor loads for Allgaier Tumbler Screeners in 2024. It covers the design and how these machines work. It also talks about what affects their load capacity and how to spread loads evenly.

By following these tips, professionals can make their material handling better. They can improve performance, efficiency, and safety. The case studies show how these ideas work in real life.

As Allgaier screening tech gets better, knowing about floor loads is key. It helps businesses stay ahead and succeed in the long run. By using these best practices, companies can make their Allgaier Tumbler Screeners work better and last longer.

This guide is a great tool for industry experts. It helps them deal with floor load issues and get the most out of their Allgaier Tumbler Screening systems. By using these new ideas, businesses can be ready for the future. They can do well in the changing world of material handling and processing.